This is the first of three parts of our special on composites in watchmaking. Part 1 sees watch editor Ashok go into the nitty gritty of what composites are and how they figure in watchmaking. Part 2 will run through in brief the history of composite materials throughout human civilisation while Part 3 will feature contemporary use of composites and recent engineering feats in watchmaking.

As children, we often learn about the strength of groups versus that of individuals, and a commonplace story on the subject goes like this: a single stick is easily broken, but get a bunch of them together and they get pretty tough. This becomes even more obvious when the individual sticks are bound tightly to each other, with strings for example. Apart from the metaphorical implications here, there are plenty of intriguing engineering propositions to consider, and it seems humans have been intrigued for a good long while about the possibilities.

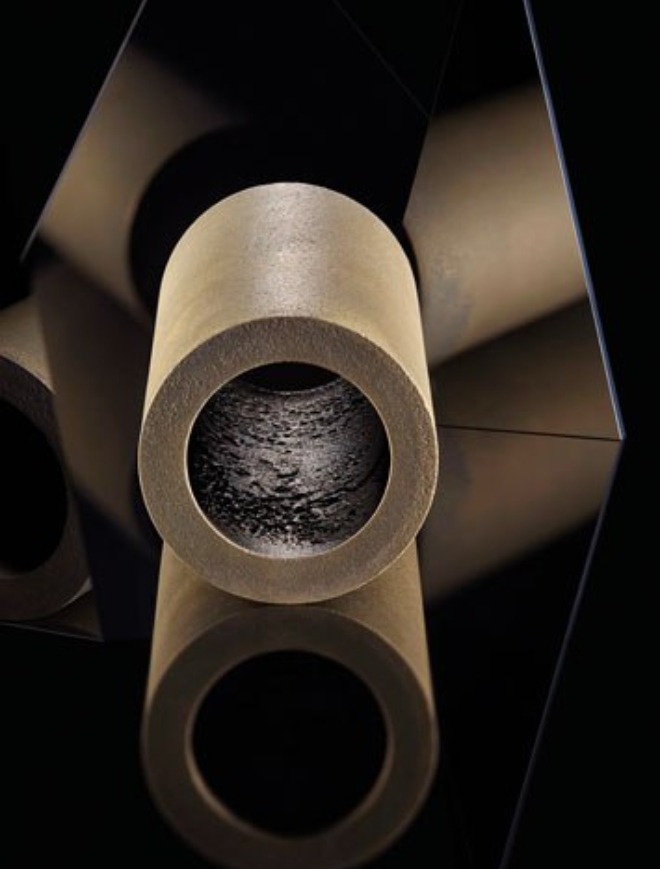

If you are anything like us, you have taken a look at the image we have chosen to open with, the title and description (which we call a deck or a standfirst) to reasonably conclude that we are going to be diving deep into the composites. No doubt this introduction will have reinforced this, but you would only be half right because we are actually covering crystals and composites. We have chosen this approach not because the materials are related (they are, but also not — it is complicated) but because they offer a brilliant visual contrast. For example, most of the images of watches in this special feature the typical weave of carbon fibre — perhaps the most famous composite material in watchmaking — and every single one is topped by sapphire crystal.

To address misgivings here, the example of sticks we opened with is missing a little something to properly qualify as a composite, and we will address that in this introduction below. As for sapphire crystal, we think it is fair to say that no one ever entertained ideas of machining structures out of sapphire, or even of producing such crystals artificially. Indeed, both composites and manufactured crystals owe much to advances in chemistry after the industrial revolution of the 19th century. Yes, there will be a history lesson and a primer on the science behind specific composites and crystals used in watchmaking, but first, some definitions are required.

Exclusivity Redefined

In previous material special segments, we have repeatedly hammered home points about exclusivity and rarity. The important thing here to note is that watch brands love a good story, especially when it can be seamlessly woven into the narrative of any given model. Broadly speaking, the entire industry looks into metals (shorthand for alloys), high-tech ceramics, crystals (mainly sapphire, which is technically a mineral in crystal form) and composites, and does so for a variety of reasons. As you might imagine, these reasons have everything to do with the properties of the material and thus involves the fascinating world of materials science.

Precious metals are a no-brainer, including the various proprietary alloys touted as the next best thing since yellow gold, but of special note here is the aptly named Magic Gold by Hublot. While we will be getting into this material in due course, we wanted to bring it to the fore because it highlights key misunderstandings about composite materials primarily having to do with alloys but also amorphous materials and ceramic. To illustrate this, here is what ChatGPT says when you ask it to define composite materials:

“Composite materials are materials that consist of two or more different materials that are combined to form a new material with improved properties. The individual materials maintain their distinct properties, but together they create a new material that has enhanced strength, stiffness and other desirable characteristics. Composite materials can be made from a variety of materials, including polymers, metals, ceramics and natural materials, and they are commonly used in industries such as aerospace, automotive, construction and sports equipment among others.”

There is nothing amiss with this definition technically, but it lacks real examples, instead repeating the word “materials” as a pseudoscientific mantra. Plywood, for instance, is a composite most of us have some experience with. While that clarifies the sort of materials we are looking at in this story, one still wonders why exactly composites have found favour in fine watchmaking. How is plywood rare or exclusive? And how, for that matter, can a composite like this be a reasonable case material in high-end watchmaking?

Of course, plywood is neither rare nor exclusive, and no watchmaking brand has ever advanced the idea of casing a CHF3,000 and above watch in this material as far as we know. Having said that, imagine if you had a proprietary sort of plywood — an engineered wood that only your firm could use because you developed it from scratch. Re-enter the aforementioned proprietary material from Hublot. Magic Gold is a combination of gold and ceramic, which is a composite called cermet (ceramic and metal) or more formally an MMC (metal matrix composite). It was developed by the École polytechnique fédérale de Lausanne (EPFL) and Hublot and is today only available at the LVMH brand. It is certainly not the only sort of cermet or ceramic-metal hybrid out there, although there is some confusion about what to call such materials since things are a bit loosey-goosey; MMC is much more specific.

Magic Gold

As noted earlier, Hublot flexed its materials science muscle in 2012 with its demonstration of the properties of Magic Gold. While the manufacture was known for its forward-thinking ways prior to this, its fame was tied closely to synthetic materials. Hublot also has a proprietary gold alloy called King Gold which owes its superior reddish hue to a higher-than-normal mix of copper, but this achievement was dwarfed by the arrival of Magic Gold, a type of MMC. Hublot is certainly not the only watch brand experimenting with MMCs but we focus on them here because Magic Gold is probably the most familiar material for watch cases and remains a part of their core collections – Cerachrom and Ceragold are a different matter.

When it debuted, Magic Gold promised a golden revolution of sorts because it was meant to be a scratch-resistant gold alloy. It does not take expert knowledge to realise that gold is a relatively soft and dense metal that is prone to scratching — steel is significantly harder but no less of a scratch magnet, as they say in watch collecting circles. Hublot’s mission was to create and deliver a material that would qualify as 18k gold (as most gold watch cases are) that also exhibited a degree of scratch-resistance that was all but impossible for a metal alloy. The manufacture decided to add ceramic (either as continuous strands or particulates) to a gold matrix to achieve this end. Nothing like this had been tried before in watchmaking so Hublot turned to the materials science experts at the EPFL in Switzerland The manufacture has its own research and development facility, but fundamental research is impossible to do in a silo.

The materials specialists began with selecting their raw materials. This included 24k gold, aluminium and boron carbide — boron carbide is a ceramic and the third hardest substance known to humans. The proportions used were as follows: 75 percent gold, 3 percent aluminium and 22 percent boron carbide. Boron carbide powder is first compacted into a desired shape before being sintered to form a porous solid. Pure molten 24k gold is then forced into these pores under 200 bars of pressure – Hublot once described this as forcing water into a room full of footballs. This revealing metaphor indicates that rather than the ceramic being the matrix that holds gold, it is the other way around. This is perfectly in line with Magic Gold being an MMC of course. Needless to say, Magic Gold is harder and more resistant to scratches than traditional gold alloys, while still maintaining the luxurious appearance and properties of gold. How tough is it, exactly? Well, apparently only diamond tools can make a dent in Magic Gold.

To machine Magic Gold, computer numerical control machines equipped with ultrasonic cutters and diamond-tipped tools had to be specially ordered from Germany. Our last update on Magic Gold noted that 28 bezels in Magic Gold took three weeks to machine with only between 30 and 40 complete cases being produced monthly. This is unlikely to have changed as Magic Gold remains truly rare in the Hublot assortment. It is no small thing that this innovation remains in play with more than 10 years now of testing Magic Gold in the wild. No solution is perfect, and Magic Gold may yet receive an update in the years to come.

Critical Clarifications

When it comes to the second material du jour, we can also look to Hublot where fundamental research into material properties is all in day’s work. While we cited the brand’s Magic Gold for composites, the manufacture is also famed for its coloured sapphire crystal cases and now bracelets — it developed these new visual flavours of sapphire crystal in its research facility in Nyon. Crystals are solid materials whose constituent atoms are organised into highly structured lattices, which is really what distinguishes them from metals. Sapphire or the mineral corundum, for example, is actually aluminium oxide or Al2O3, but what makes it a crystal or mineral is how the atoms are arranged. This is why you have probably heard that diamonds and graphite are the same thing, except with different atomic structures.

In the same vein, crystals or minerals should not be considered ceramics although they might share the same atoms and even some characteristics. The mineral corundum is the natural form of aluminium oxide in its crystalline polymorphic phase. All minerals are crystals while some organic or synthetic matter can take crystalline form, but those are not minerals.

We will end this introduction with a quick note about the production of synthetic sapphire crystals, which is much more recent affair compared with composites. A quick definition, once more helpfully supplied by our friendly AI assistant: “A synthetic sapphire crystal is a man-made crystal composed of alumina that exhibits properties similar to natural sapphire and is used in various applications that require high optical clarity, scratch resistance and durability.”

Material Storytelling

Once again, this definition is basically right, though it should be noted that the alumina the definition refers to is of course Al2O3, which is exactly what corundum is made of. Unlike composites, human beings have only been creating synthetic sapphire crystal since the 19th century and our ability to efficiently make large shapes out of this material (in smartphone screens and optical lenses, for example) is relatively recent. Even the crystals that protect the dials of our watches are considered large in this context. It is worth mentioning before we move on that crystals can also be turned into composites and thus one might fairly call the coloured sapphire crystals at Hublot composites too.

If it is not clear (no pun intended), sapphire crystal has its preeminent place in watchmaking because of its properties, especially its hardness and exceptional clarity. When quizzed on this, Hublot is emphatic about maintaining the durability aspect in the sapphire crystal composites it develops. This brings us back to the point about the properties of the materials being of paramount importance for the purpose they are used, or perhaps the purpose dictated that a specific material was called for. An example of this is the use of ceramic ball bearings in the automatic winding system at A. Lange & Söhne for the Odysseus — it just made sense, given the sporty character of that watch.

So yes, this story will not pretend that a new-fangled material was required because the watch collector of the 21st century needs to be kitted out as if he commutes to Mars for work, or will be using his Kevlar watch dial to absorb the kinetic punch of a bullet (a missed opportunity in John Wick, probably because Carl F. Bucherer has not deployed bullet-proof dials). Oftentimes, it is simply about the empowering feeling that such a material can deliver and the lengths the watchmaker went to in order to adapt it for use in wristwatches.

This is a reference to both Hublot and Richard Mille, arguably the strongest proponents of exotic materials in watchmaking. Richard Mille, with the seminal RM009, proved that lightweight watches could justify an exorbitant pricetag (and command the relevant prestige) if the watchmaker put in the right amount of effort. These two brands, alongside IWC, Panerai and Roger Dubuis, will figure strongly in the story that follows. For me, this is because the Alusic proprietary MMC used in the RM009 was the moment I discovered that proper materials science had a place in the making of traditional watches, and in the marketing of the same! Not for nothing, it was the first time I had heard of MMC and it really got me deep diving into materials science. Like so much about contemporary haute horlogerie, you can thank or blame Richard Mille for this, dear reader. In case you are wondering, you can also blame the lack of clarity on the per gramme price of composites on the Richard Mille phenomenon, if not the brand itself.

And with that, the history lesson on composite materials can begin (Head over here for Part 2 of the story).

This article was first published on Issue #69 of World of Watches.

For more reads on watches, click here.